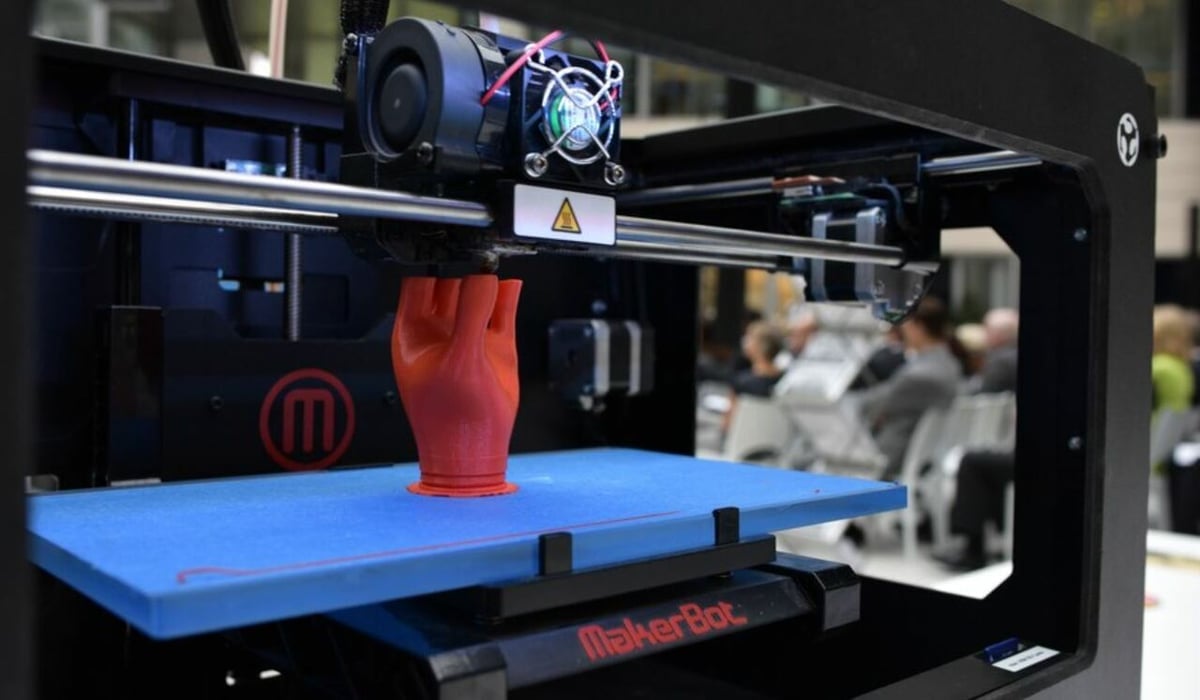

Polylactic acid, known as PLA, is a thermoplastic and the most utilized 3D printing filament. The king of FDM 3D printing, PLA is known for its ease of use, requiring a relatively low extrusion temperature of around 180 °C and no minimum bed temperature.

PLA is also considered a bioplastic, meaning it’s a plastic that’s made from renewable materials and which should be biodegradable. While PLA is definitely unique from most other plastics in how it’s made, its biodegradability is a commonly disputed topic.

In this article, we’ll be diving into PLA’s material composition, production process, biodegradation, environmental implications, and more.

Composition

PLA is considered a bioplastic because it’s produced with materials sourced from renewable biomass products. That means it’s made up of lactic acid units, which are small organic acids similar to those found in many foods we encounter on a daily basis – think sourdough bread, yogurt, soy sauce, and of course, corn. In fact, anything with glucose can theoretically be transformed into lactic acid molecules.

These lactic acid units are the basis for PLA plastic and account for PLA’s overall weak mechanical properties and helpful printing properties. For example, the lactic acid in PLA has low crystallinity, causing it to have a low glass transition temperature. (Check out more details in this paper from the Shaanxi University of Technology.)

This low glass transition temperature, among other factors, makes PLA parts easy to melt and manipulate, which is why it’s easy to 3D print. However, this low glass transition value is also the reason PLA parts are relatively brittle and weak.

Other common 3D printing materials, such as PETG (a derived version of the PET bioplastic) and ABS (a petroleum-based plastic), tend to have higher strength but are more difficult to print. That’s because they’re not made up of molecules that correspond to PLA’s lactic acid units, with their polymers generally having higher crystallinity. This higher crystallinity causes a higher glass transition temperature, making them stronger but harder to print.

Additives

Many PLA filaments also contain other chemical components and materials, known as additives. Additives dilute the “purity” of the PLA, but in return, they make the material more practical for 3D printing or other purposes.

There are many different additives used in the plastic production industry, and each has a unique composition and purpose. Plastic manufacturers typically employ distinct blends of additives to accompany a base material, like PLA. Among other things, these blends account for variation in material properties, printing performance, and color. (PLA is naturally a clear, milky color.)

As an example, most PLA+ filaments are meant to be stronger than regular PLA filaments, and manufacturers achieve this by using impact modifier additives. This type of additive is specifically meant to make the plastic less brittle and more impact resistant. Examples of impact modifier additives used in some 3D printing filaments include those from Sukano Polymer and Arkema Incorporated.

Production

While PLA plastic may be a bioplastic made out of crops that you can grow in your backyard, there are many steps in the PLA production process. This means that the only people who are really capable of making it are professional manufacturers with access to the expensive machinery necessary. In this section, we’ll review the production process for PLA plastic, specifically PLA filament.

Extraction & Creation

The first step is sourcing the raw materials for PLA. As we’ve said, PLA consists of lactic acids, which can be taken from organisms and plants that contain glucose. Corn is one of the most common plants used to generate the lactic acids for PLA filaments, as it contains a decent amount of glucose.

To extract the lactic acids from the corn, the plant undergoes a process known as wet milling, which retrieves the starch from the organism. Then, the starch is combined and heated with other chemicals to isolate the dextrose, more commonly known as sugar. After this happens, the dextrose is fermented to attain lactic acid monomers.

The lactic acids are used to make the PLA plastic through one of two special processes: polymerization, which is more common, or condensation. These processes cohere the lactic acid molecules using chemical assistants and heat, which in turn, produce the PLA plastic. To learn how this plastic is converted to filament, you can check out our main article on how filaments are made.

Consequences

Theoretically, PLA plastic is a renewable bioplastic because it’s sourced from the lactic acids of renewable plants. However, these plants are only the starting point for making PLA plastic; many additive chemicals and intense processes are also used. As such, while the PLA in a PLA product might be considered biodegradable, additives, such as impact modifiers, may be less or not biodegradable.

The time it takes for a material to degrade is dependent on its crystallinity, with a direct correlation between the two aspects. The lower the material’s crystallinity, the easier it is for microorganisms responsible for biodegradation to chemically break down the material. As we’ve mentioned, PLA has a pretty low crystallinity compared to other, especially petroleum-based, plastics. However, if you mix in additives that have a higher crystallinity, the biodegradability of the final product will worsen, taking longer to degrade.

On top of this, there are many artificial and unnatural processes that go into making a PLA product, including fermentation, polymerization or condensation, and the use of chemical assistants. These processes may chemically affect the biodegradability of certain components, again hurting the environmental friendliness of the PLA product. For example, polymerization increases the crystallinity of polymers, thus causing the material to take longer to decompose.

In the end, although PLA may seem like it should be biodegradable because it’s made from plants, you have to consider the biodegradability of the other production materials and processes.

Biodegradation

Now that you know what PLA is made of and where it comes from, it’s time to discuss its biodegradability. In this section, we’ll go over several factors that contribute to how well it can or can’t degrade.

The Breakdown Process

Contrary to the belief often associated with materials that are considered biodegradable, PLA can take hundreds of years to degrade in an environment like a composter or a landfill.

Indeed, just leaving a PLA part outside for years is unlikely to have any effect on its plastic composition. This was demonstrated by YouTuber Hobby Hoarder, who buried a few 3DBenchys in a backyard for two years. After they were recovered, tests showed that the parts, while a good bit weaker, had no clear physical signs of biodegradation and were still basically 100% intact.

While not a controlled scientific experiment, the video does a good job of representing the reality behind PLA’s biodegradability: It doesn’t break down easily. In fact, some sources go as far to say that PLA, while degradable, isn’t biodegradable on the grounds that the conditions required for PLA to effectively biodegrade are rare in natural environments.

In the end, it’s important to remember that PLA is still a plastic material and all plastics, including bioplastics that originally came from plants, don’t biodegrade easily. There is, however, a way to speed this up: specialized, industrial-grade facilities.

Strict Environment Requirements

Essentially the only way to effectively biodegrade PLA is in a unique, controlled environment. There are two main conditions that must be met to produce this environment, and they typically require the use of industrial-grade equipment and facilities.

- Microbes: The first condition is a high number of microorganisms, which can eat away at the PLA, thereby breaking down the plastic on a chemical level. This is essential for all biodegradation, but to really have a strong effect on PLA, an abundance of microorganisms is required, even more than what’s usually present in a batch of standard, microbe-rich soil.

- Heat: The second condition is heat. PLA has a glass transition temperature of around 60 °C, meaning a part made of PLA will start to soften and begin to melt at this temperature. As it’s heated, PLA deforms and releases air, taking up less space and allowing microbes to more effectively break down the plastic.

Note that melting PLA doesn’t directly contribute to its degradation; it’s simply required for the required biological and chemical processes. For example, microbes only begin to degrade PLA at temperatures above 30 °C.

Lastly, it’s important to biodegrade PLA parts in a humid environment. As discovered in one study, increased humidity leads to an increased rate of hydrolysis, which is the chemical breakdown of a material.

So is PLA biodegradable? Not really. Unless you’re sending your PLA parts to industrial composting facilities, they’re likely sit alongside their ABS and PETG counterparts for centuries to come.

Implications

While PLA is arguably technically biodegradable, practically, it’s not. At the same time, how biodegradable PLA is partially depends on your perspective.

If you’re comparing PLA to a strawberry, then the bioplastic is clearly much worse: Natural fruits such as strawberries tend to take no more than a week to completely biodegrade and return to the environment. On the other hand, the biodegradability of PLA can look good compared to that of other plastics, such as ABS or the plastics used in plastic bags.

Other Plastics

Most other plastics, including ABS, are petroleum-based, meaning they’re made from oil. ABS and similar plastics, such as the ones used in plastic bags, take at minimum hundreds of years to decompose naturally. As they aren’t composed of natural materials, it’s harder for microorganisms to break them down and, even when decomposed, oil-based plastics will continue to harm the environment. From this perspective, PLA can perhaps be considered a more environmentally-friendly choice as far as filament goes.

Biodegradable PLA Plastic

Although PLA isn’t naturally biodegradable, some PLA-focused products offer enhanced biodegradability or other environment-focused properties. If you’re trying to reduce your plastic footprint but still want to have the advantages of using PLA plastic, you may want to check these brands and products out.

One somewhat popular option is Earth Nurture’s special additive. Earth Nurture claims that their masterbatch additive can improve PLA plastic’s biodegradability by stimulating microbes to eat away at any PLA.

Other products also provide more environmentally-friendly aspects, even if they aren’t more biodegradable. For example, you can purchase waste PLA filament that’s been thrown out or is deemed unusable. 3D printer filament brands like Protopasta sell their imperfect filament, including PLA plastic, at a discounted rate. Plus, you’re helping prevent this plastic from becoming waste.

Recycling

Finally, if the goal is to reduce one’s plastic footprint, recycling PLA is a good way to prevent it from becoming waste. Recycling PLA can be done in a few ways, including recycling the plastic directly or purchasing previously recycled filament.

Although not as easily recyclable as cardboard, when done properly, PLA can be recycled and reused. As a thermoplastic, you can melt PLA into a liquid state, allowing the material to be easily manipulated and turned around for another use. (Many other plastics can’t be recycled this way, especially thermosets, which form irreversible chemical bonds.)

There are two primary ways to recycle your waste PLA plastic, specifically 3D printed PLA. The first is to take your PLA to a special recycling center that accepts this type of plastic. (In most countries, you can’t simply throw PLA in the recycling bin with your other plastics.) To do this, search for specialized recycling centers in your area. You may have to pay a fee, but it’s better than dropping a garbage bag of failed prints off at a landfill!

The second way to recycle your excess PLA is to do it yourself, using a filament recycler and filament extruder. With a filament recycler, you can cut and grind your wasted PLA into small pieces and pellets. Then, load these pellets into a filament extruder, which will grind, melt, and cool them into filament that you can later use.

While not actually recycling PLA, the last thing you can do is purchase recycled PLA plastic. Recycled PLA isn’t as compromised as you might think; you can check out our article all about recycled PLA plastic filaments to learn more about this type of filament and find a few great brands to get you started.

Lead image source: tc_fea via Thingiverse

License: The text of "Is PLA Actually Biodegrable?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.